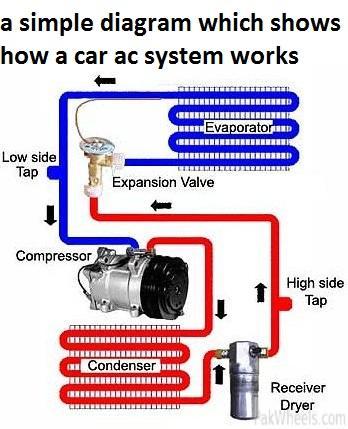

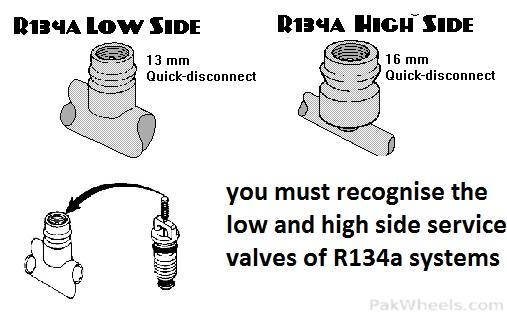

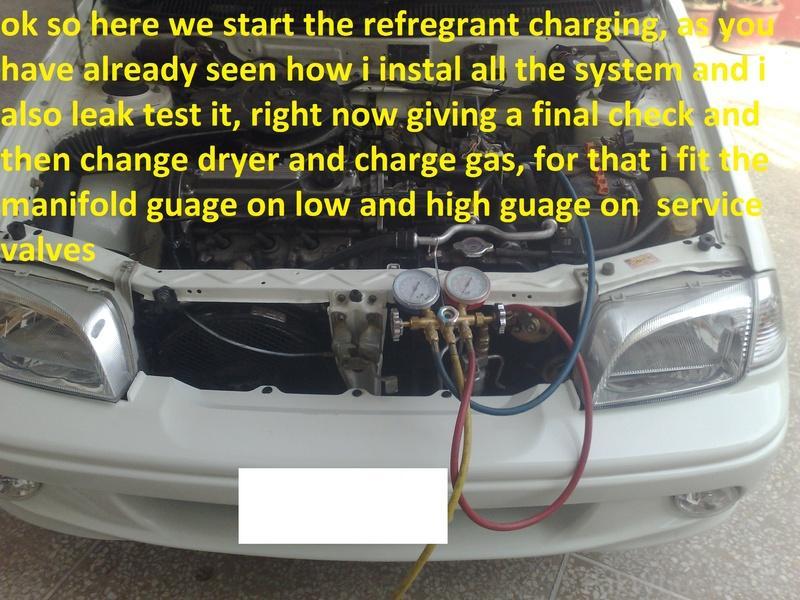

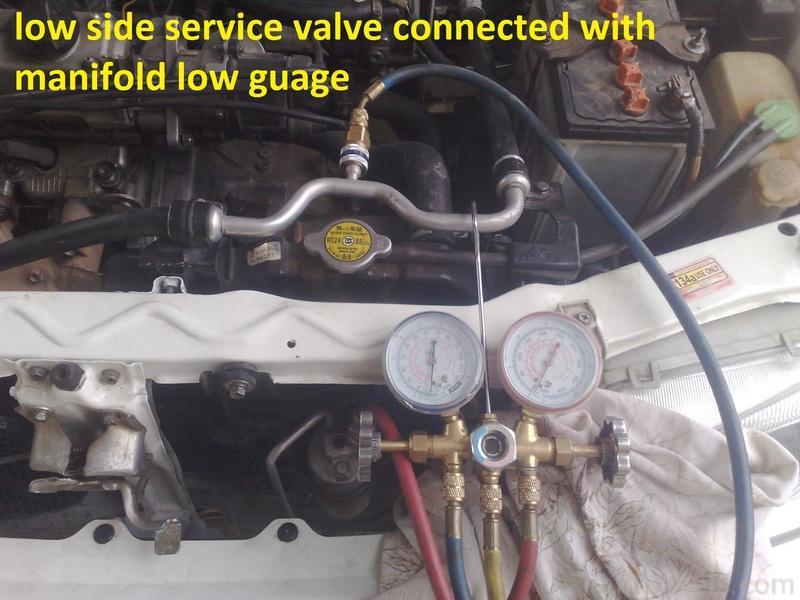

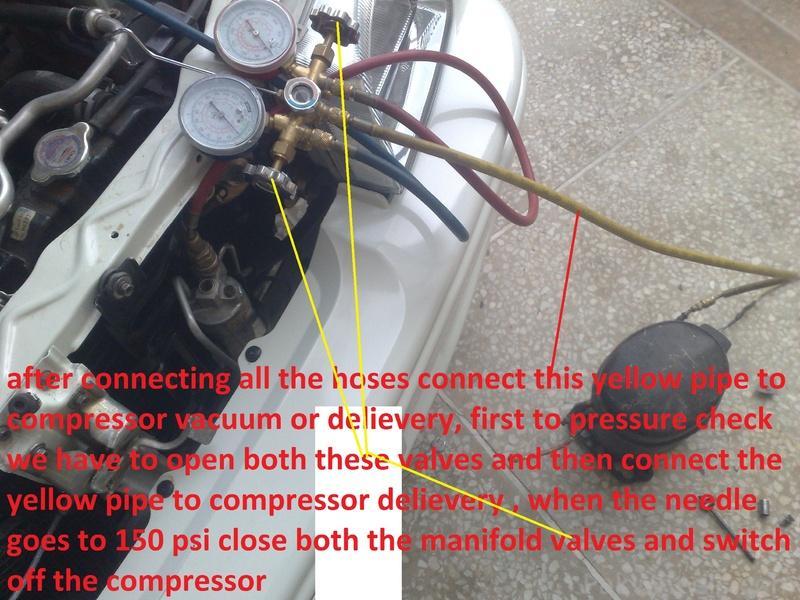

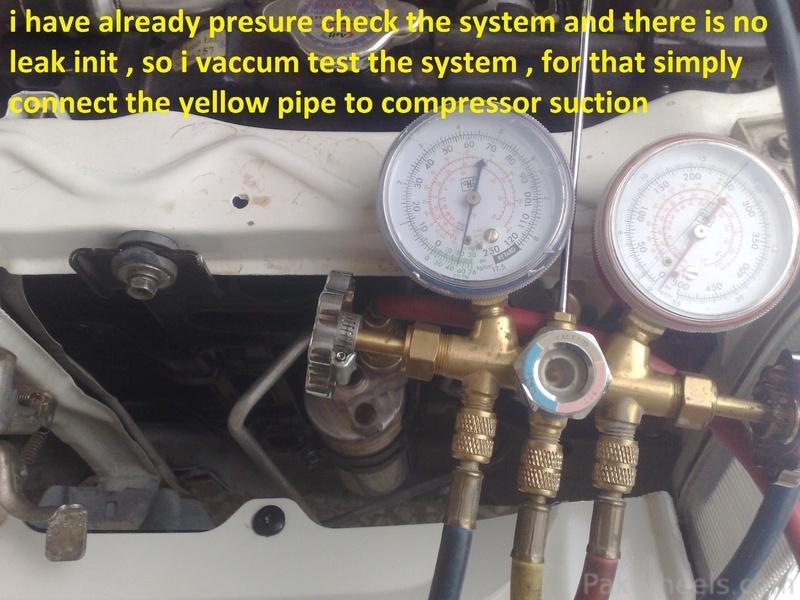

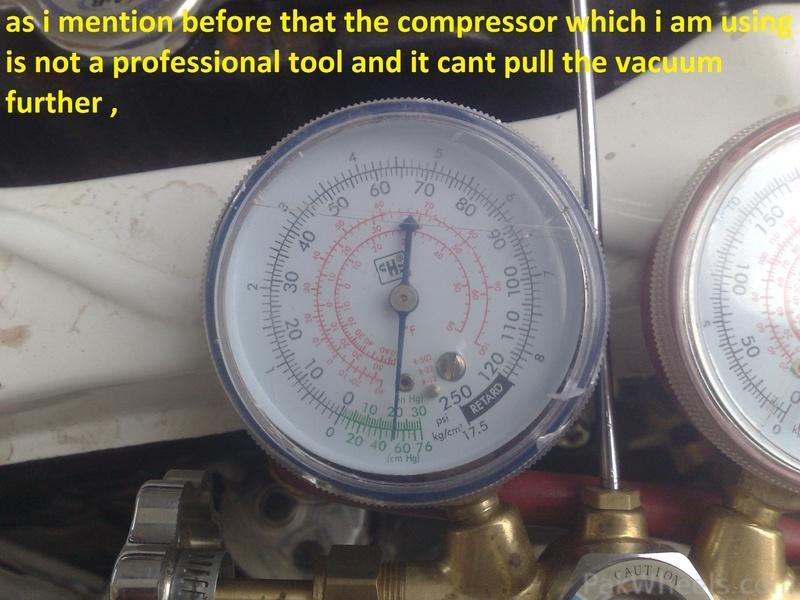

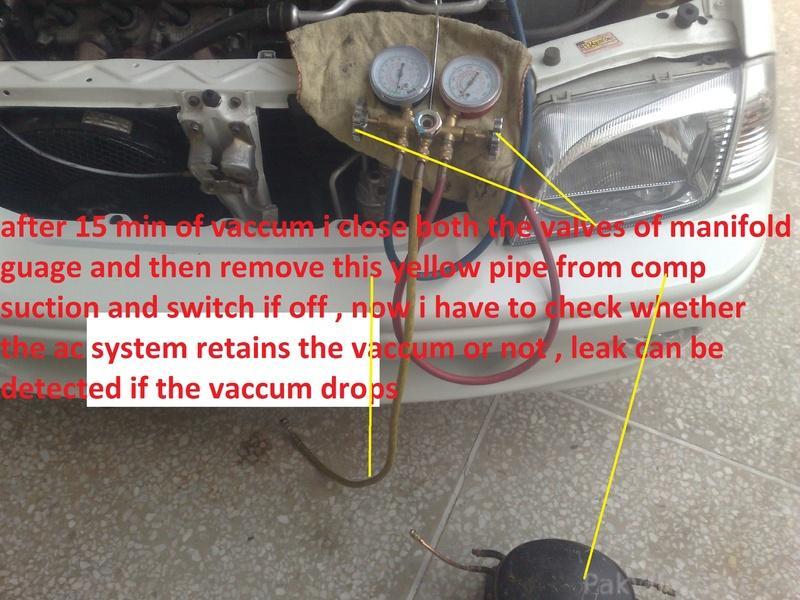

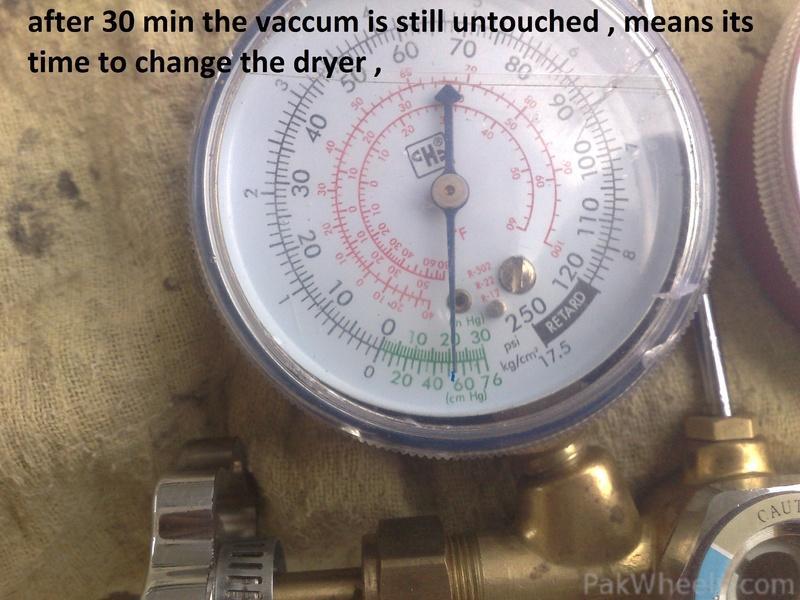

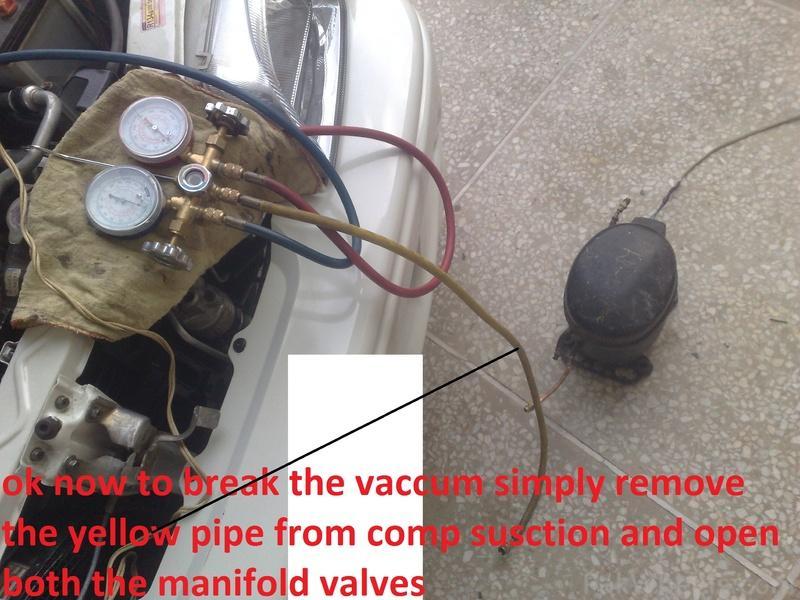

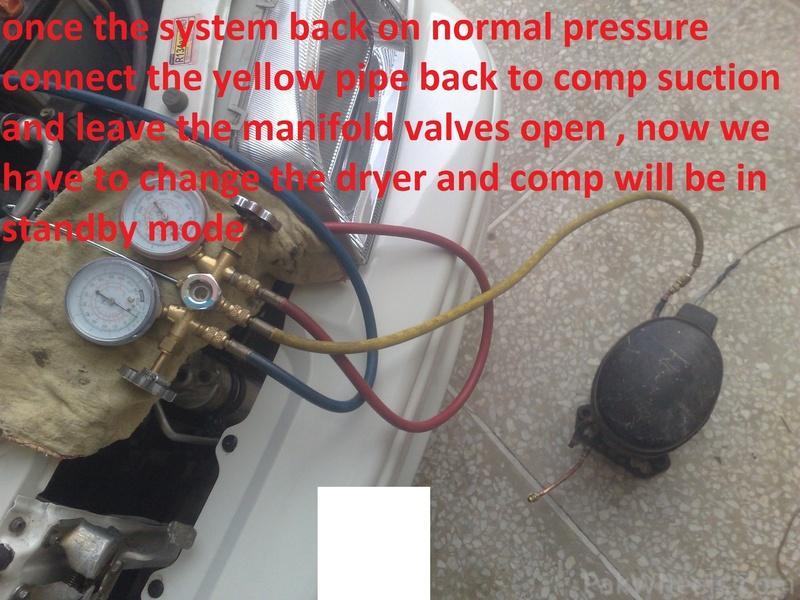

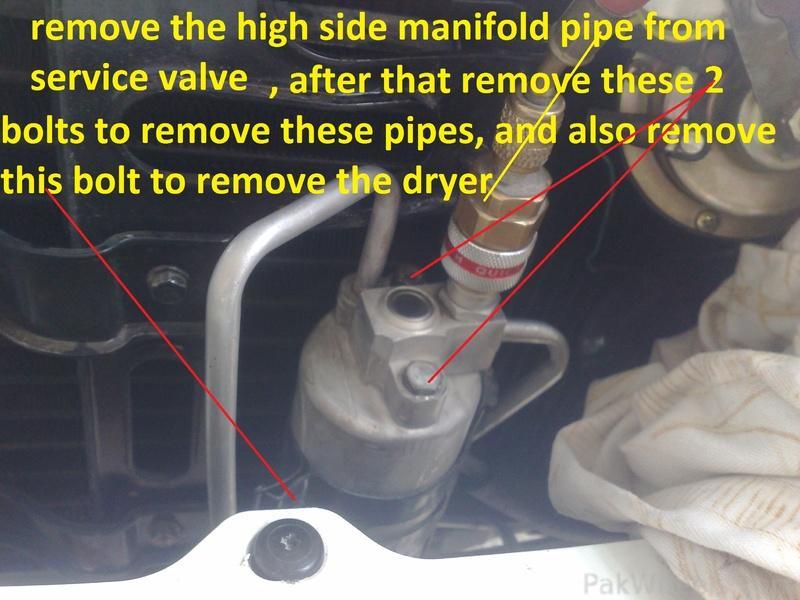

Helo PWs , here I charge refrigerant in ac system , as you have already seen how i have flushed and installed back all the system , right now the only thing left is the final leak test , then change dryer and charge gas , I guess it a very very easy task and you can easily do that if you have proper tools , there is nothing high tech in it, still I haven’t see any ac shop doing all that in proper way, I have also done few blunders but I have no other option , first one is that you have to use nitrogen gas instead of air to pressure check the system , as you know that there is no moisture in nitrogen gas so it’s a best deal to use nitrogen to pressure check the system , but its not possible for me/us so I use compressed air which is full of moisture , second thing is using leak detecting dye for leak test , I try my best to find that but fails , most of the shop keeper even never listen about such thing , so again no option other than first pressured with air (instead of nitrogen) and then use a surf liquid to check leak,,,,,,,,,if you find any leaking O ring then change it with original one , local one wont last long especially when system heat up ,

<FONT face=Arial><FONT size=2><FONT face=Verdana>One thing I wont able to share with you is the expansion valve service , I take its pic but unfortunately I lost some of my data during data transfer from one pc to other , expansion valve is the alternate of orifice tube which reduces pressure, and I never see any car ac system with orifice tube but there are car ac systems which come with orifice tube , any how all Pakistani cars comes with expansion valve systems , which some times get stuck and need service/replacement , it s installed inside the evaporator casing under the dash board , simply remove it and flush it , I gave it a test by putting its sensor in cold water , it was working fine so I haven’t change it , if it need to change then buy 100% same , in my case the ac system is filled with steel mesh of broken compressor , means it really need some serious service/flushing from inside and for that I use CTC which you guys have already seen , I guess you can use carburetor cleaner as well as it also evaporated very quickly and leave no residues , always remove all the O rings before flushing with CTC as it can damage the rubber , one more thing I want to say that you can easily flush the evaporator and condenser with the system compressor installed in car , its little tricky but possible , but I recommend you batter buy a external compressor because you cant charge refrigerant without that, <?xml:namespace prefix = o ns = "urn:schemas-microsoft-com <TBODY><TR style="mso-yfti-irow: 0; mso-yfti-firstrow: yes"><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT: windowtext 1pt solid; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 6.65in; PADDING-RIGHT: 5.4pt; BORDER-TOP: windowtext 1pt solid; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt" vAlign=top width=638 colSpan=3>

<TBODY><TR style="mso-yfti-irow: 0; mso-yfti-firstrow: yes"><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT: windowtext 1pt solid; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 6.65in; PADDING-RIGHT: 5.4pt; BORDER-TOP: windowtext 1pt solid; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt" vAlign=top width=638 colSpan=3>

R 134a Ambient Temperature Pressure Chart<o:p></o:p>

</TD></TR><TR style="mso-yfti-irow: 1"><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT: windowtext 1pt solid; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt" vAlign=top width=213>

Ambient Temperature °F/°C<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

Low-Pressure Gauge<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

High-Pressure Gauge<o:p></o:p>

</TD></TR><TR style="mso-yfti-irow: 2"><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT: windowtext 1pt solid; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt" vAlign=top width=213>

65°F (18°C)<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

25-35 psi / 172-241 kPa<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

135-155 psi / 931-1069 kPa<o:p></o:p>

</TD></TR><TR style="mso-yfti-irow: 3"><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT: windowtext 1pt solid; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt" vAlign=top width=213>

70°F (21°C)<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

35-40 psi / 241-276 kPa<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

145-160 psi / 1000-1103 kPa<o:p></o:p>

</TD></TR><TR style="mso-yfti-irow: 4"><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT: windowtext 1pt solid; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt" vAlign=top width=213>

75°F (24°C)<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

35-45 psi / 241-310 kPa<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

150-170 psi / 1034-1172 kPa<o:p></o:p>

</TD></TR><TR style="mso-yfti-irow: 5"><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT: windowtext 1pt solid; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt" vAlign=top width=213>

80°F (27°C)<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

40-50 psi / 276-345 kPa<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

175-210 psi / 1207-1448 kPa<o:p></o:p>

</TD></TR><TR style="mso-yfti-irow: 6"><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT: windowtext 1pt solid; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt" vAlign=top width=213>

85°F (29°C)<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

45-55 psi / 310-379 kPa<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

225-250 psi / 1551-1724 kPa<o:p></o:p>

</TD></TR><TR style="mso-yfti-irow: 7"><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT: windowtext 1pt solid; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt" vAlign=top width=213>

90°F (32°C)<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

45-55 psi / 310-379 kPa<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

250-270 psi / 1724-1862 kPa<o:p></o:p>

</TD></TR><TR style="mso-yfti-irow: 8"><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT: windowtext 1pt solid; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt" vAlign=top width=213>

95°F (27°C)<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

50-55 psi / 345-379 kPa<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

275-300 psi / 1896-2068 kPa<o:p></o:p>

</TD></TR><TR style="mso-yfti-irow: 9"><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT: windowtext 1pt solid; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt" vAlign=top width=213>

100°F (38°C)<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

50-55 psi / 345-379 kPa<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

315-325 psi / 2172-2241 kPa<o:p></o:p>

</TD></TR><TR style="mso-yfti-irow: 10"><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT: windowtext 1pt solid; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt" vAlign=top width=213>

105°F (27°C)<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

50-55 psi / 345-379 kPa<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

330-335 psi / 2275-2310 kPa<o:p></o:p>

</TD></TR><TR style="mso-yfti-irow: 11; mso-yfti-lastrow: yes"><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT: windowtext 1pt solid; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt" vAlign=top width=213>

110°F (27°C)<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

50-55 psi / 345-379 kPa<o:p></o:p>

</TD><TD style="BORDER-BOTTOM: windowtext 1pt solid; BORDER-LEFT:

#f0f0f0; PADDING-BOTTOM: 0in; BACKGROUND-COLOR: transparent; PADDING-LEFT: 5.4pt; WIDTH: 159.6pt; PADDING-RIGHT: 5.4pt; BORDER-TOP:

#f0f0f0; BORDER-RIGHT: windowtext 1pt solid; PADDING-TOP: 0in; mso-border-alt: solid windowtext .5pt; mso-border-top-alt: solid windowtext .5pt; mso-border-left-alt: solid windowtext .5pt" vAlign=top width=213>

340-345 psi / 2344-2379 kPa<o:p></o:p>

</TD></TR></TBODY></TABLE>

<o:p></o:p>

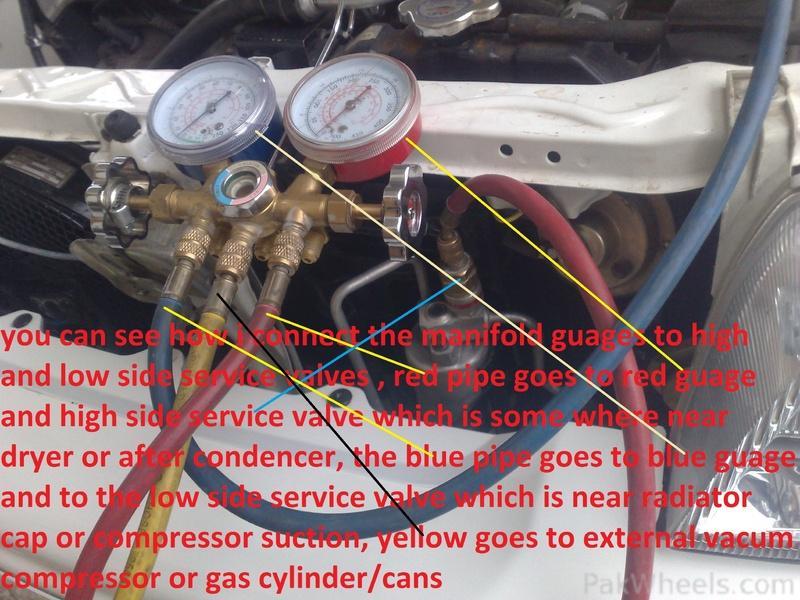

When I charge the gas the ambient temp was 28DC , means my low and high side pressure must be between 40-50 and 175-210 psi respectively , I don’t know how ac shops charge gas with out looking at ambient temp , one thing you have listen from them is that the low side pressure must be around 20 psi , don’t know the logic behind all that , and many ac shops just connect one guage with low side only , no need to check the high side , again no logic for that , always remember that you have to take the reading of high and low side guage while the engine is running on stable RPM of about 1500 , its very important

<o:p></o:p>

LOW pressure gauge ,,,,,,,,,,,,When the reading is between 25 and 40 psi with the A/C running, stop charging at that time . The system is fully charged and should be cooling normally. DO NOT add any more refrigerant. If the gauge is over 50 psi, you have overcharged the system with too much refrigerant. ,,,,,,,,,,,High pressure gauge,When the reading gets up around to 250 psi, stop charging , The system is fully charged and should be cooling normally. DO NOT add any more refrigerant.<o:p></o:p>

If the low side and the high side pressure is low that indicate low charge,,,,,,,,,,,,If the low side is low and the high side is high that indicate the blockage in the expansion valve ,,,,,,,,,,If the low side is high and the high side is low and if the gauges needles are vibrating than it mean there is a fault in compressor valves ,,,,,,,,,,,,If the low side and your high side are high that means system is over charge, stop pressure is over 100 psi.,,,,,,,,,,,,,,If low side is closer to 30 then colder the car is and if the high side is closer to 150 then colder the car is

One more thing is that you have to be careful about the comp oil , you must use the right oil in the right quantity , oil grade and quantity usually stamped on the back of compressor , so batter buy you own oil and take it to the ac shop and ask the ac mechanic to first flush the compressor by that new oil and then remove all the oil from the comp and then fill the new and clean oil in the exact quantity , Pour the oil very slowly into the intake port or low side of the compressor. This is where the large line entered. While pouring in the refrigerant oil, rotate the hub and clutch slowly to let the oil enter the compressor. Once that is completed, lay the compressor down on the hub for 10 minutes to let the oil seep into and lubricate the front seals to prevent leaks on startup. , I have seen ac mechanic use old comp oil which is pulled from the kitchen fridge and freezer compressor , that oil has a typical smell and a experienced person can easily find out what the hell is that , that oil cant be used in R134a units , and also it cant be mixed with the oil which is already there in the compressor , so I suggest pull the comp out and first flush it with new oil , and then fill it with new oil ,

That’s it for now and this is the last major post of this thread , few more will come soon like compression and engine oil pressure check ,

Any how check the pic they will mostly speak them self

Best of luck ,