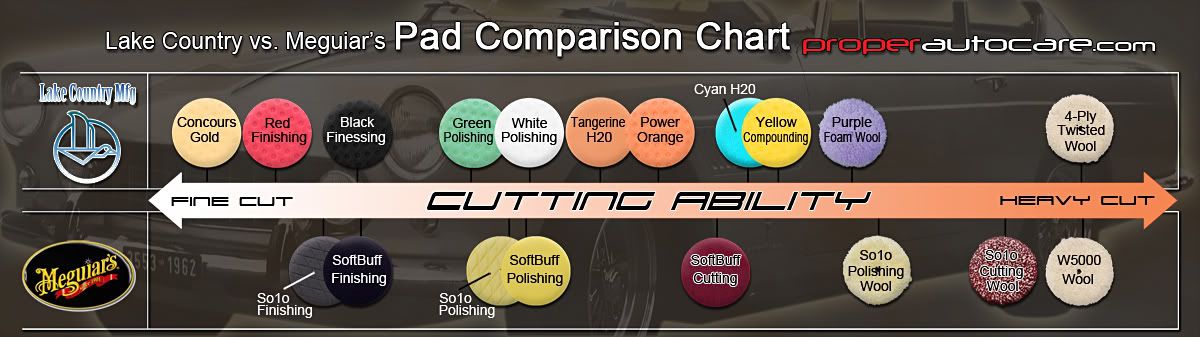

So for your reference here is a picture that I hope would give you a fair comparison of the pads out there and how the Meguiars one compare to them.

So if you see the Meguiars burgundy pad matches very closely with the LC CCS orange pad and I can tell you from experience that these pads generate a decent amount of cut as well.

Coming to the other problem that you pointed out is the PC power, which most people say as well and it is true. Though it's not as underpowered as you might think. It does bog down but most DA polishers will except for the flex 3401. As you work with it you will realise that it has a lot of potential and you will find an ideal balance of how much pressure you can apply.

I'm going to go a bit more technical here and hopefully all the machine polishing fanatics can correct me and add to this. /

For how long did you keep the pressure on the pads when you applied gentle pressure and achieved the cut, was it through out, was it just for a few passes, the initial passes or the end ?

How many passes did you do per section with the cutting pad ?

What was the speed of your pass ? Did you cover a 2x2 area in under 10 seconds or did you give it a full minute for a 2x2 section ?

And perhaps this is more important, how big of a portion were you working on ? Half the panel, quarter of a panel or the full panel in one go ?

I hope you get some answers to your questions. Tell me what you infer out of this and we can carry on from there

P.S Umar dont take my questioning in a wrong way or that I dont appreciate your effort. I love your results just want you to think more before detailing and explore the potential of your products !