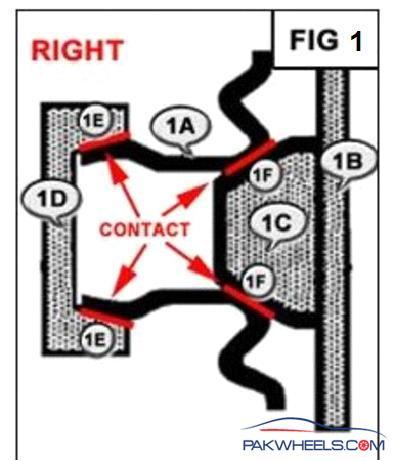

I have been driving this car about a bit, basically to the shops nearby (less than 2km) and found that the right front spinner becomes loose after each trip. This is very dangerous and I cretainly can't go 12km to the paint shop. That is like driving your car with the wheel nuts loose. After much investigation and experimentation I have found out that there is a problem with the front right spinner. Based on research and teaching myself a bit of engineering about wire wheels I found that the wire wheel is supported on the tapers of the hub and spinner. See figure 1 below. This is a crude sketch where the wire wheel is 1A, the hub is 1C, spinner is 1D, and the correct contact points are at 1F and 1E.

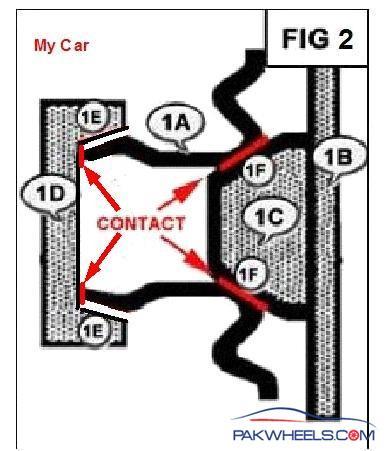

I used Prussian Blue to see the contact points in my car and found that the spinner was not contacting the wheel in the correct place. See Figure 2 below relating to my car. Note the contact point 1E. The spinner is contacting the wheel at the face rather than the taper. That is why the spinner is opening up as the wheel turns.

For those who are not familiar with such wheels, the spinners tighten in a direction opposite to wheel travel. That is the right side spinners have a left hand thread and the left side spinners have right hand threads. This is so that as the car drives the centrifugal forces on the spinners are always causing the spinners to tighten.

Back to the problem at hand. What to do? Two solutions presented themselves to me. One - To machine the spinner in a way that it would tighten to the point the spinner would grip the wheel at the taper. Two - Was to provide a taper spacer of the same degree a the spinner thick enough to take up the space between it and the wheel.

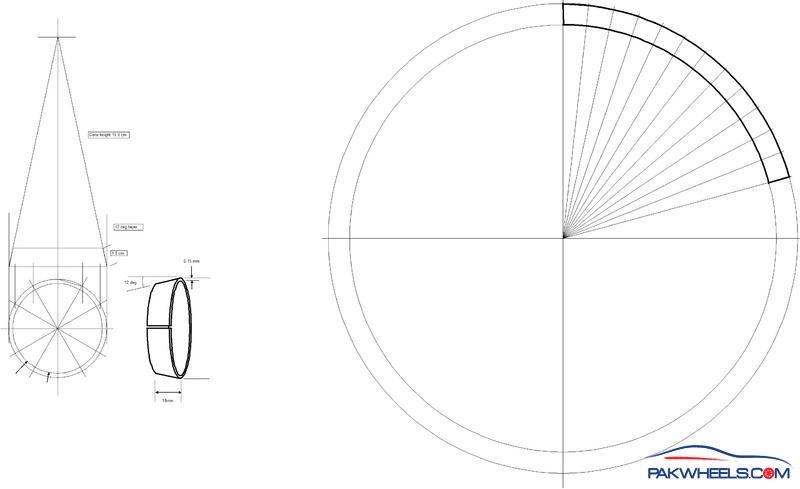

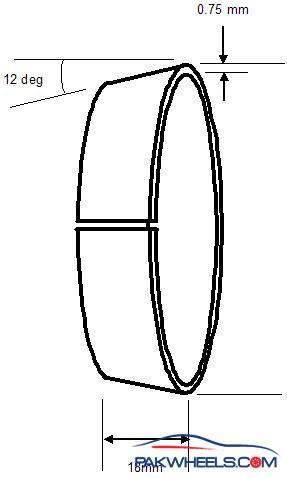

After careful calculation I found out that if I opted for "one" the spinner would become dangerously weak. So there was no option but to go for option two. I pulled out my old drafting book from university days and revisited the method on how to manufacture a truncated cone. Measurements told me that I needed a 0.75mm thick spacer with a 12 degree taper with a width of 18mm.

Fabrication was done by yours truly based on the following drawing I made for the required part out of 0.75mm thick sheet. Here are the working drawing followed by a close up of the actual spacer.

The spacer in real life

Happy to say that since fixing of the spacer the spinner is no longer coming loose and neither has the integrity of the spinner been compromised.

Now we are all set to go to the paint shop.