Achi tara samajh gaye

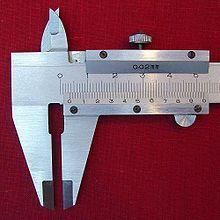

Oh my God, I didn't see the bush. Now that you have mentioned it, I can clearly see it now! I have to say that it was very clever of you to think of this idea. Again I have to repeat myself in saying that you MUST measure things such as clearances and interferences to ensure that the engine will not explode or destroy itself at high RPM. Your engine is rated at 36 BHP @ 10500 RPM. 10500 is a very high revving engine. As a first step you could buy yourself a simple vernier.

This is for very rough measurements, better than a measuring tape but not good for fine measurements such as bearings. Not too expensive maybe 1000/- or so

The next better tool than this one will be much more expensive, a micrometer perhaps 1-2 inch or 2-3 inch depending on your needs.

This one is the ultimate tool for measuring outer diameters. The problem with this one is that they can only measure in intervals of 1 inch (25mm). You will have to buy 2 or 3 of them to be able to do your engine. Due to high cost maybe you will not want to invest. This will measure up to 0.01 mm

For measuring bores or holes is a bore gauge - very, very expensive:

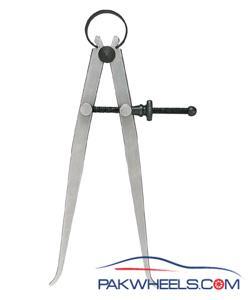

Cheaper alternative is this which can be used is an inside caliper. This is used in conjunction with a micrometer:

But still going back to measurements, you HAVE to make sure of this. Why I am stressing this is because critical original parts have been modified.

Buffing the parts is looking good. As far as deciding to colour a few parts, That is totally your choice. If I was doing the job, I would have everything the way it came from the factory but you might like to customize it. Have a look at the web for ideas.