Lets enlighten you all by sharing a bit of information on most of the pre-production elements of automotive design. These include the creative elements of vehicle development, such as sketching and modelling, as well as other important considerations, namely aerodynamics and ergonomics.

h11. Aerodynamics/h1

Aerodynamics is a highly refined science that vies for position with other key vehicle design considerations such as styling and ergonomics. It's importance with respect to the operating efficiencies of a vehicle is undisputed but manufacturers must steer a balanced path between the push an pull of the many other aspects of a car necessary to sell it to the consumer.

Aerodynamics started life as much as an art as a science. Early experiments used fish as the inspiration. Their sleek form was considered important to facilitate fast movement, but the precise details were not yet understood and developments were largely based on trial and error. It was as a result of this approach that the 'teardrop' form was conceived.

Wind tunnel testing for modern vehicles

Aerodynamic work on the 1960s Ford GT programme

Pressure Sensitive Paint

h1Aerodynamic Considerations/h1

Aerodynamic factors, considered carefully, can improve many aspects of a vehicle. Some key aerodynamic considerations have been summarised here.

[(vi) refers to Road Vehicle Aerodynamic Design by R.H. Barnard]

With an object moving through a fluid, the wake is extremely significant. When considering family vehicles, the nature of the vehicle’s rear, in three dimensions, can make the difference between a low or a high coefficient of drag (Cd).

Improvements at the front can be made by ensuring the ‘front end is made as a smooth, continuous curve originating from the line of the front bumper’. On normal two and three box shapes, drag is often caused by high pressure just upstream of the front windscreen, ‘often with a separation bubble of recirculating air at the base of the screen’. The magnitude of this effect depends upon the windscreen ‘rake angle’. Making the screen more raked (ie. not as upright) ‘tends to reduce the pressure at the base of the screen, and to lower the drag’. However, much of this improvement arrives because a more sloped screen means a softer angle at the top where it meets the roof, keeping flow attached. Similar results can be achieved through a suitably curved roof.

Design in plan as well as profile, is significant. ‘Curving the windscreen in plan view modifies the flow patterns considerably ... which reduces the extent and intensity of high pressure.’

The A-post is also an issue: ‘A strong outward cross-flow can occur towards the edges of the windscreen, tending to produce separated vortices around the A-posts.’ These effects can be minimised by smoothing the form of the A-post and increasing the curvature of both the A-post and the screen. Smoothing the transition from the body to door mirror is also significant as it can otherwise be a major source of drag and wind noise.

At the rear of vehicles, the ideal format is a long and gradual slope. As this is not practical, it has been found that ‘raising and/or lengthening the boot generally reduces the drag”.

Results of research state that drag due to rear slope angle will be at its ‘peak at 30º and minimum at around 10º’.

Increasing the curvature of the roofline will also reduce the drag coefficient. Benefits are gained by bringing the roof line down at the front and rear. Simply ‘bulging the roofline up’ however, may cause such an increase in frontal area that any gains may be negated.

In plan view, rounding corners and ‘all forward facing elements’ will reduce drag. Increases in curvature of the entire vehicle in plan will usually decrease drag provided that frontal area is not increased. ‘Tapering the rear in plan view’, usually from the rear wheel arch backwards, ‘can produce a significant reduction in drag’. Under the vehicle, a smooth surface is desirable as it can reduce both vehicle drag and surface friction drag. ‘For a body in moderate proximity to the ground, the ideal shape would have some curvature on the underside.’

In (vi), the author lists the following significant areas for thought when attempting to design a typical car (not a sports car or commercial vehicle):

- Smooth unbroken contours with favourable pressure gradients as far back as practical should be used.

- Strongly unfavourable pressure gradients at the rear should be avoided; some taper and rear end rounding should be used.

- The form should produce negligible lift.

A If a hatchback configuration is required, the backlight angle should not be in the region of 30º, and if a notchback (saloon) is to be used, the effective slope angle (ie. the angle of a direct line between the roof and the highest, most rearward point) should also not be in the region of 30º.

- The underbody should be as smooth and continuous as possible, and should sweep up slightly at the rear,

- There should be no sharp angles (except where it is necessary to avoid cross-wind instability).

- The front end should start at a low stagnation line, and curve up in a continuous line.

- The front screen should be raked as much as is practical.

- All body panels should have a minimal gap.

- Glazing should be flush with the surface as much as possible.

- All details such as door handles should be smoothly integrated within the contours.

- Excrescences should be avoided as far as possible; windscreen wipers should park out of the airflow.

- Minor items such as wheel trims and wing mirrors should be optimised using wind-tunnel testing.

- The cooling system needs to be designed for low drag.

Although aerodynamic concerns are not as strong in this vehicle as they may be in a sports car, for example, the basic principles outlined here should be observed throughout the design process. Energy efficiency can be improved with low drag and low levels of wind noise improve passenger comfort.

h12. Ergonomics & Anthropometrics/h1

ergonomics

the scientific study of people and their working conditions, especially done in order to improve effectiveness

(Source: Cambridge Dictionary)

anthropometrics

Anthropometrics is the comparative study of human body measurements and properties.

(Source: University of Texas Online)

Ergonomics, or human factors engineering, is, loosely speaking, the science of designing for the human form and human behaviour. As a field, ergonomics covers everything from door handles and buttons to vehicle proportions and door apertures. With the increasing use of information technology within cars, ergonomics is becoming a major consideration in the design of user interfaces and information and entertainment systems.

h3

Considering Humans/h3

People vary dramatically in size and proportion around the world. Scandinavian men are amongst the tallest whilst far eastern women are among the shortest. Similar variations appear in other factors - width (at various points of the body), hand size, reach, weight and so on. Traditionally these factors have largely depended upon the geographical location of a person - and how humans have developed over thousands of years. However, lifestyle is increasingly affecting the physical attributes of people. A particular example is the increasing levels of obesity in western countries, especially the US. This dramatically affects average figures for dimensions such as width as well as movement and reach considerations.

Another very major issue affecting designers is the increasing life expectancy of people. This is particularly pertinant in developed countries but will increasingly affect all developing countries. As life expectancy increases, people perform tasks and activities for longer and later in life. At the same time, people may experience a deterioration in mobility and dexterity. Here lies another important ergonomic consideration - designing for people who may have trouble with awkward controls, openings and other features of a vehicle whilst still expecting to use the vehicle to its fullest. Changes in response to these concerns can be seen on almost every new car - exterior door handles are often larger, simpler and bolder than a decade or more previously.

h3Models and Mannequins/h3

Within the automotive industry, representative models and mannequins are used to form the basis for vehicle size and form. Tradionally, these would be simple, actual size 2D models based on the Dreyfusshuman dimension data. Henry Dreyfuss was a pioneer of human measurement and captured the first significant data on human measurement. This method has been superceded by computer models which have been developed from more recent data.

h13. Modelling/h1

Developing a vehicle is an arduous process of design and evaluation, trial and error - constant improvement and adaptation. Initial design concepts go through a range of stages to bring them closer to realisation and modelling is key to evaluating a design at each stage.

Modelling can take several forms. Traditionally, clay models have been used at various scales to help understand and resolve the form and proportions of a vehicle. To varying degrees, this has been supplemented, sometimes even replaced, by CAD modelling. Whilst clay is still a medium used to evaluate predominantly visual characteristics, CAD systems can additionally help evaluate other factors such as aerodynamics, impact scenarios and other physical considerations.

h3Clay Modelling/h3

Clay modelling is one of the most established 3D visualisation techniques used in the automotive industry.

h3CAD Modelling/h3

Computers are now used to accelerate virtually every aspect of vehicle development. Computer aided design (CAD) modelling allows designers and engineers to resolve increasingly large amounts of a vehicle before even the first model is made.

h3Additional Modelling Processes/h3

There are other processes involved in modelling, and sometimes entirely different approaches.

*I will post the details of Sub-Headings of Modelling later.

h14. Sketching/h1

The earliest stage of the design process is the creation of initial concept sketches. The sketches are a relatively quick way to visualise ideas, themes and styles. In a typical design studio, a team of designers may be asked to submit initial ideas for a vehicle which will subsequently be narrowed down and further developed. Often, a dozen or so initial ideas will be evaluated, with further development of two or three before a final solution is chosen. At each stage, designers whose work is not chosen will be redeployed to assist in the development of the chosen ideas or posted to another project. Typically, one team is responsible for the interior whilst another takes charge of the exterior.

As the sketches develop, more time will be spent on creating resolved an accurate views. These drawings will form the basis for a simple package and, in the later stages, will be developed alongside a scale model clay or CAD model.

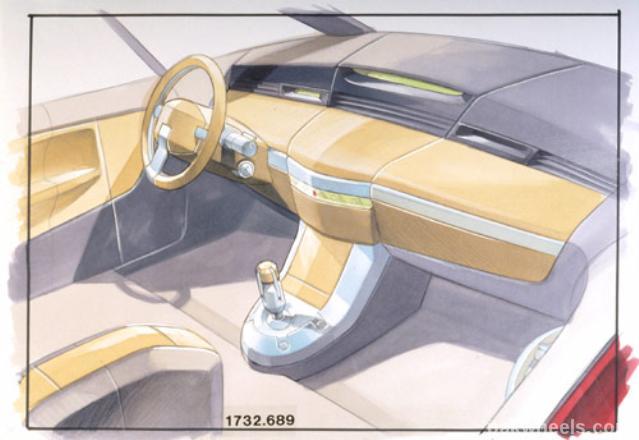

The interior rendering above is a hand-drawn, highly finished view of the dashboard of the Avantime. Following initial ideas, after resolving the view, proportions and perspective a rendering like this is produced. It is drawn lightly in pencil before colour is added using markers. This illustration uses mainly light yellows and cool greys. The metallic effect is achieved by banding white with very light blues. Additional light, shade and line definition is added with coloured pencil. Light mapping lines (as visible vertically on the driver's door) are sometimes used to help illustrate changes in form in addition to colour and tone.

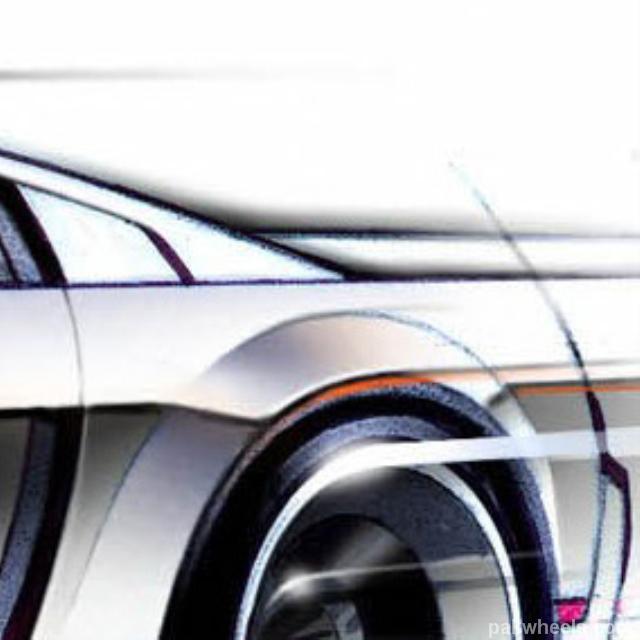

This illustration of Ford's Mustang GT Coupe concept has most likely been developed from a sketch and then reworked in a programme such as Adobe Photoshop.

The image is particularly powerful because of its crisp lines and blurred movement effect. Creating this effect is arduous with traditional airbrush techniques but is far more straight-forward in Photoshop.

First of all, an image is scanned in and cleaned up, removing unwanted elements and adjusting the brightness and contrast. To create the airbrushed effects, a path is drawn around an area - accurately demarcating the section to be airbrushed.

Then, the path is made into a selection marquee, a new layer is created and the desired brush tool can be used within the specific area. This can be repeated and adjusted until the right result is achieved. Each section in turn is treated this way; this is not the only process involved, but it is the most significant.