Another blast from the past!!

h1Bmw Concept Coupe Mille Miglia 2006 - Design process/h1

Detailed information and images from the design process of the BMW Concept Coupe Mille Miglia 2006, that provides hints of design and function for production cars in the far future.

The BMW Concept Coupé Mille Miglia 2006 pays homage to the skills, successes and the visions of the motor sports pioneers of the past, created by its modern successors.

The BMW Concept Coupé is a symbol of how much the values internalised by the creators of the 1940 BMW 328 still determine the work of the engineers today.

The Concept Coupé Mille Miglia 2006 is neither a copy of a successful racing car nor is it being used as a herald for future series models.

According to BMW, the Concept Coupé's design "provides hints of design and function opportunities, which can be made practical for series production vehicles used only in the far future."

h2Design/h2

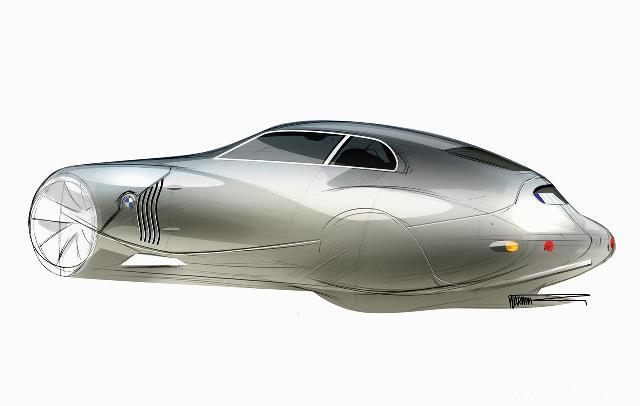

The bodywork design is oriented on the BMW 328 Mille Miglia Touring Coupé, that legendary two-seater with which Fritz Huschke von Hanstein and Walter Bäumer drove home the victory during the Mille Miglia in 1940.

The BMW Concept Coupé is based on the BMW Z4 Coupé. Compared with it, the Concept is longer (23 centimetres), wider (14 centimetres wider) and lower (4 centimetres). On the other hand, the tail section is markedly gentle and stretched wide for aerodynamic reasons.

Inspired by the 1940 Bmw 328, the basic design of the Concept Coupé was interpreted in a modern manner.

The front of the Concept Coupé ensures a striking appearance in a completely new manner, but especially guarantees better vision.

At first glance the “face” of the study appears familiar, its “eyes” remind one of the circular headlamp used in the BMW 328. But they are not integrated into the chassis – rather they have been attached as flat elements.

Modern LED technology facilitates accommodating powerful light sources in comparatively small units. This progress provides the designs with new possibilities. The forms and linework from the engine hood to the wheelhouses in the Concept Coupé can be continued up through the front apron without being interrupted by the headlight units.

The optically dominating role on the front end is taken over by the BMW kidney. More than ever, it characterises the typical BMW “face” by letting the headlights take over the role of the “eye”, despite the innovative execution.

Aerodynamics

The aerodynamics, already distinctive in the 1940 Mille Miglia winner, took advantage of modern technology: five each optically impressive air intakes near the A-pillars control the flow movements in the front end.

In the BMW Concept Coupé, these ports, arranged in a very slim Z-line, fulfil a two-fold function. On the one hand, they lead off the air used for engine cooling back out through the BMW kidney.

In addition, underpressure is generated in the front wheelhouses at the same time. This effect reduces the turbulences at the wheel housings and simultaneously amplifies the vehicle’s contact pressure with the road.

The entire trim over the rear wheels and the extremely gently coasting tail are additional design elements based on both the traditional and the latest aerodynamic findings.

A reverse V-form thus arises as the sum total, minimising undesired turbulences and concentrating the flow separation to a tightly restricted area.

Trimmings placed on the underbody and diffusers made of carbon on the front and rear aprons also ensure defined air conductance in those parts of the body that are not openly seen.

In the body design, the functions needed for positioning the engine, drive units and passenger sections are combined into an aesthetic whole together with the aerodynamic requirements.

h2Design Elements/h2

The 20-inch alloy wheels, specifically developed for the BMW Concept Coupé, fit into the image of its powerful proportions. Tyres dimensioned 245/40 R 20 are mounted on them.

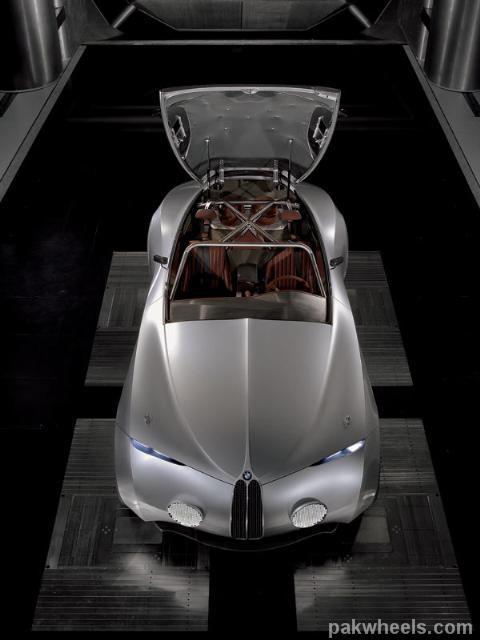

Instead of doors, the study bears permanently integrated sidewalls, contributing to weight reduction on the one hand and to increasing torsional stiffness on the other. To let the pilot access the interior, the entire cockpit swings up. The rear section of the concept study is also distinguished through design elements in which the aesthetics are tightly connected with their function.

The headlight panel, made from LED elements is likewise conducted in a gentle Z-curve horizontally over the tail. The combination of the most modern illumination engineering and their unusual design unites two functional advantages: due to the extremely fast response time of the LED’s and through the increased conspicuousness of their asymmetrical layout, the brake lights can be perceived earlier than with conventional lighting.

The BMW Concept Coupé's body form "is not dictated by nostalgia, but rather by the endeavour for forward-looking interpretations for typical BMW design themes.

"The study is proof that the vehicle designers at BMW have a grip on the art of accepting traditional impulses and letting them flow into new designs with the help of modern expertise. That is the only way that concepts can mature – by combining the power of history with the fascination of visions and letting emotions be awakened at the same time."

h2Prototype construction/h2

While developing the BMW Concept Coupé, traditional methods were applied: emotional models based on emotional designs emerge from the hands of experienced modellers.

Whereas the nearly unlimited possibilities of high-tech designing on a computer always involve the danger of randomness, in traditional body design only consequent implementation of an idea leads to the desired goal.

That is also a reason that the design models for all BMW Group models emerge made-by-hand even today.

During series development, this is done with clay models – a malleable Plasticine mass. For the Concept Coupé, the designers fell back on even more traditional methods: modelling with plaster.

This material entails fixed work rhythms during the application, shaping and hardening of the material. Each and every step demands a high degree of concentration. During both of these optically and haptically tangible processes of evolution, the designers form an especially tight relationship to their design object.

During the material selection, developers choose an extremely light chassis: at Touring in Milan, an aluminium shell was stretched over a lattice frame.

Nowadays plastics developed especially for chassis construction set the standard for lightness, load ratings and design freedom. Accordingly, that kind of material was chosen for the Concept Coupé.

The entire body of the concept vehicle is made out of a carbon-fibre reinforced plastic (CFRP). The shell is painted fine silver, a full-gloss paint colour with extremely fine pigments. In this way, the finish awakens the memory of traditional colourings, but when inspected more closely it is clearly the result of the most modern surface-aesthetics engineering.

h2Interior Design/h2

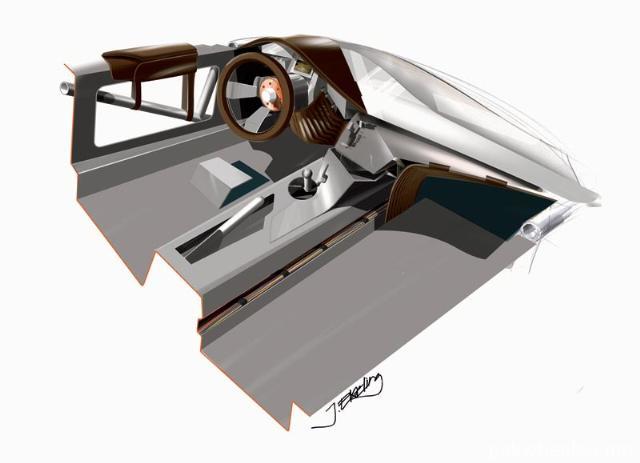

Limits on the functionality, the material selection and both the optical and haptic impression valid until now were consciously burst through; customary design and fabrication techniques were replaced by completely new methods.

Thus an interior was born in which the structure of the surfaces and forms achieve totally new effects. At the same time, gaps and contours have their own functionality; metal plied by hand impressively accentuates the characteristics of the material. All surfaces are brought out uninterrupted and unadorned. Neither decorating trim nor rings or frames impair their purist impression.

Even letterings, logos and symbols are not, for instance, additionally attached but are embossed into the respective metal component using laser technology.

Using extra-flat rolled stainless steel, untreated cowhides and Lycra fabric, a total of exactly three materials are deployed in the interior of the BMW Concept Coupé. The processing methods were also reduced to a minimum selection. All components were either stitched together or clamped to each other using a special technique. The impression of surfaces and controls resulting from this imparts the occupants an impression of ambience that is just as futuristic as exclusive.

While designing the interior elements, the designers combined the use of traditional materials and the application of innovative processing methods with each other. While doing so, they achieved a result that is unique in automobile construction and loaded with incredible effects. Especially conspicuous: the implementation of V2a stainless-steel processing in the cockpit and the centre console area. More than just the purist unpretentious material itself, that kind of shaping sets a fascinating accent.

The metal sheets, rolled to a thickness of only one millimetre, are multi-folded to take up the final surface structure of the respective component. Beforehand, the metal sheets are given a precisely cut fold on the intended edges. This is carried out using a laser technology developed especially for this purpose. This facilitates extremely exact remodelling, which leads to exceptional stability of the completed component on top of that.

Everywhere where two metal components meet, they are clamped together absolutely flush using laser cut castellations. Gaps are only present where they could and above all should take on a function at the same time; for instance, the transition between the dashboard support and the centre console is used as additional storage space. That transforms the gap from an undesirable side effect accruing when two components are connected into a consciously inserted design element. That is another way in which the interior of the BMW Concept Coupé opens up entirely new perspectives in automobile engineering.

While working the metal, the interior designers let themselves be inspired by traditional paper folding techniques. There also, forms and structures are created without artificial connections, which despite their light weights offer impressive stability. By the way, this is not the first time the art of Origami, originating in Japan, has inspired automobile construction. The folding technique used to accommodate airbags in the smallest possible space is also essentially influenced by this method. But for designing entire interior landscapes, this solution represents something of a revolutionary accent.

Connecting tradition with innovation also led to a new aesthetic when processing the leather in the BMW Concept Coupé interior. Several layers of the merely tanned, but other than that natural cowhides are pressed into each other. Thus a three dimensional leather-mould part emerges that, among other things, imparts a new haptic feeling in the seating and middle console sections. Furthermore, the undyed leather underlies a natural maturing process, leading to attractive patina effects over the years.

The leather and Lycra elements are connected among and with one another using especially subdued stitches. Even metal and leather is stitched together wherever they meet. The three materials dominating the interior of the concept vehicle consist of highly varying characters: one is a metal created for infinite solidity, one an untreated and therewith living natural material and one made of modern, hardwearing plastic fibres. Despite all these contrasts, they create an extremely attractive combination in which the aesthetic effect arises from unadulterated functionality.